Pure Direct Drive: the secret of a 10 times more precise printing

Quality and precision at the highest level for the OMET X6.0: thanks to the Pure Direct Drive technology, the machine reaches the highest level of quality currently on the market for flexo printing, eliminating any imperfection. This revolution has raised the standards of the printing world and has assessed the OMET line as one of the most requested for narrow and mid web labels and packaging.

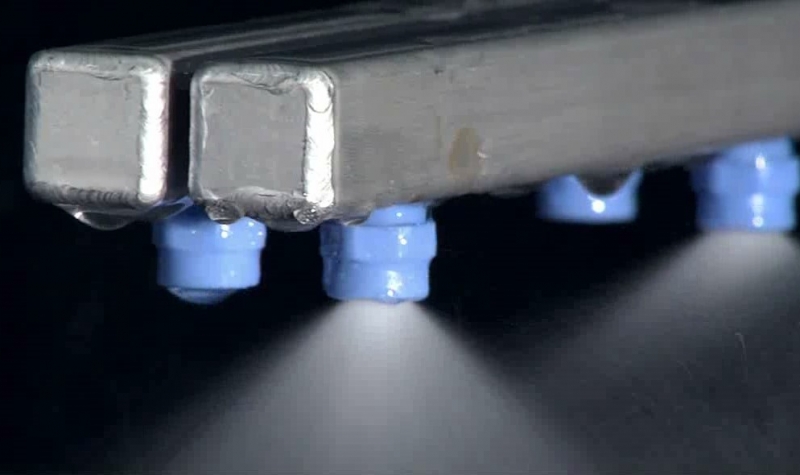

OMET X6 has been the first flexo machine with the printing stations equipped with “Direct Drive Pure” transmission on the sleeve mandrel, since its presentation in 2007 (and never equaled): this system allows perfect register stability even at the highest production speeds thanks to the “Gearless” concept with sleeve printing.

The Pure Direct Drive technology allows to control the movement without mechanical transmissions between the motor and the mandrel: this allows an absolute precision in the rotation of the printing axis, whatever it involves in terms of register precision, printing quality, dot gain control, and no backlash.

Direct Drive is much more precise and performing than the classic application used on the other printing machines for labels and flexible packaging, based on a low back lash gearbox. Considering figures, the Pure Direct Drive technology allow the machine to be 10 times more precise, reducing the play on the cliché to +/- 0.004 mm for 12″ formats (instead of +/- 0.042 mm, universally considered the standard for machines with precision reducer), and a play of +/- 0.008 mm for 24″ formats (instead of +/- 0.084 mm for machines that do not have Direct Drive).

is the web magazine with all news about OMET Group

is the web magazine with all news about OMET Group