OMET enchants at Labelexpo Europe 2019

The new OMET XFlex X7 was the “queen” of the fair. Its demos attracted an extraordinary flow of interested visitors. Great attention was also paid to the demos of the new hybrid OMET XJet powered by Durst and of the iFLEX full LED version.

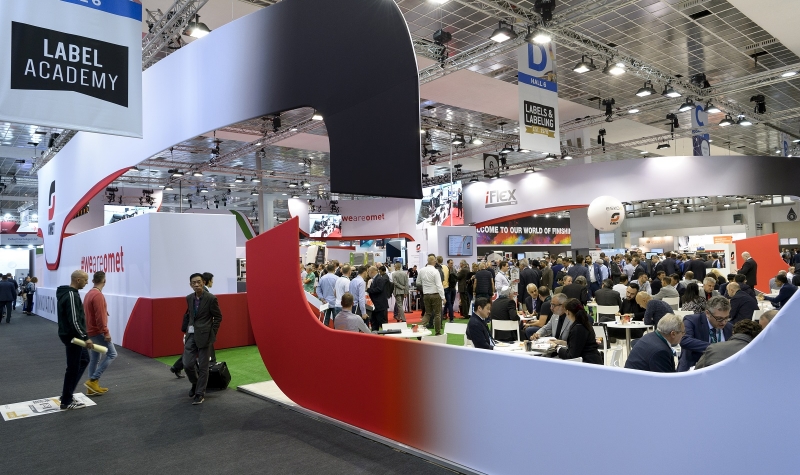

The most successful Labelexpo Europe ever for OMET!

Thanks to the number of innovations introduced by the Italian company were highly appreciated by the market, OMET generated an incredible amount of contacts. Orders worth 5M Euro were signed during at the show, and a lot of ongoing negotiations to be finalised in the coming weeks. One of the biggest and most elegant stand hosted thousands of people during the 4 days of the fair: it was a must-see stop for all visitors, intrigued by the great innovations showed by OMET.

OMET’s world’ premiere: the X7, is an actual revolution for the sector. A 670mm (26″) wide flexo-hybrid line equipped with innovative features, that integrates several printing and converting technologies in-line with a modular design. The new High Value Rotogravure printing unit (HVR) – for the first time at Labelexpo, running on water-based inks. The all new flexo station designed with Zero Gears Solution also available in the Vertical Geometry version with extended drying tunnel. X7 allows the maximum level of precision, automation, quick setup and waste control.

Another attraction for printers was the new hybrid XJet powered by Durst: the flexo+inkjet fully integrated solution, able to print the highest-quality labels and shrink sleeves. Another world premier to widen printers’ business opportunities.

The third machine on demo was iFLEX in 8-LED with a new COLD FOIL SAVER that allows considerable energy savings and FOIL saving upto 50%

The project “OMET-The green side of printing” was right the topic of the show where each printer and brand-owner showed interest around the topic of sustainability. For a long time OMET’s technological research has been paying attention to eco-sustainability, involving different aspects of the printing process: substrates, inks, energy, LED and waste reduction.

Last but not least, OMET was also presenting its role of solution provider in the “Core Linerless Solution” project for Linerless labels, in collaboration with Ritrama, Spilker and ILTI. OMET engineered the laminating module to process CLS self-adhesive film (Core Linerless Solution) for the transformation in a single ply Linerless web.

is the web magazine with all news about OMET Group

is the web magazine with all news about OMET Group