LABELEXPO 2017: iFlex, innovation made of simplicity

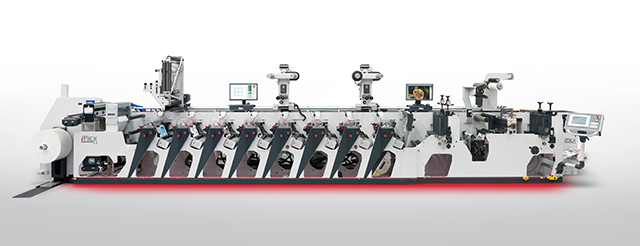

Great success for OMET at Labelexpo 2017. One of the greatest and most impressive booths of the entire exhibition welcomed thousands of visitors from all over the world, confirming OMET leadership in the European and International market. Main attractions were the three printing lines, iFlex, XFlex X6.0 and X6 Offset, presented with live demonstrations showing also the concepts of the Industry 4.0.

iFlex drew particular attention thanks to its new version with specific chill rolls, which increased the versatility of the press born to revolutionize the concept of label printing. Thanks to a set of unique innovations, it allows for perfect printing results through ease of use, intuitiveness and quick operations.

OMET iFlex is a narrow-web printing press 370 mm wide (14” 4/8), with maximum speed of 190 m/min and printing repeat from 5.5” to 18”. It offers the possibility to print with different technologies, such as flexo UV, UV LED or water-base and rotary screen printing, with in-line die-cutting (repeat from 8” to 24”).

iFlex is a Made in Italy narrow-web press dedicated to the label market, able to produce all kind of labels with the highest efficiency, including wraparound and shrink labels, thanks to the possibility to implement the specific Film Asset. It is the ideal solution to start a new business in the label market, a growing sector attracting more and more players, or to enhance an already qualified machine range, since it is perfect for both short and long runs.

Its main strong point is the functional design: it features short web path to minimize start-up waste and it requires low maintenance and minimum spare parts thanks to its compact but very ergonomic design, poor for wearing components, making it a real cost-effective solution. It features unique smart applications, specifically conceived to make the entire printing process easier and intuitive.

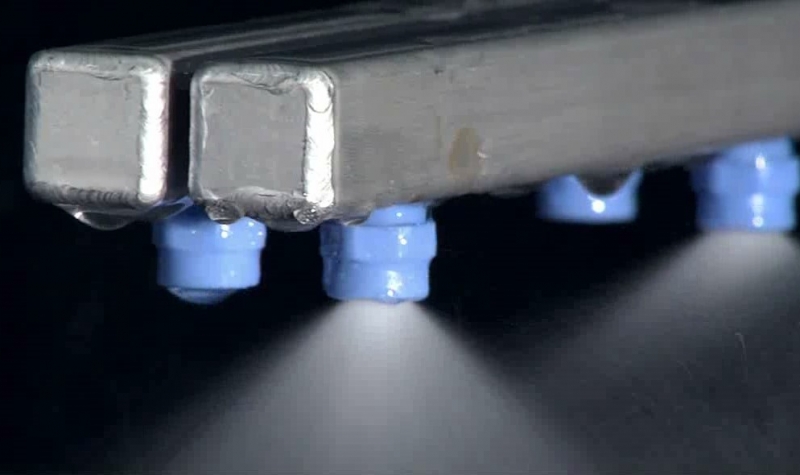

iLight is an innovative pre-registration system with laser pointer on every flexo unit. The laser beam indicates the ideal alignment of the print cylinder, allowing quicker job changeover and register set-up. A second laser system is installed inside the die-cutting unit to help the operator in positioning the flexible die with no mistakes. iVision is the innovative register adjustment system allowing for color-to-color register setting in real-time, through a set of smart cameras, one on each printing unit. The operator needs few seconds to adjust the mark just by watching the image on the dedicated display. iLight and iVision combination drastically reduces set-up time and waste, making every operation extremely easy and intuitive.

Like all OMET printing lines, iFlex offers a superior print quality thanks to a new direct driven transmission on the impression cylinder: iDrive. This exclusive system increases the print precision and erase the common issues of flexo printing: it is the only narrow-web press with only one gear per print unit, which enables better performance and higher stability, without any gear mark issue.

iFlex is a complete line configurable with different finishing and converting options. The Easy-Change Die-Cut unit with ECDC system eliminates long changeover time through a special sliding device, which facilitates the handling of heavy magnetic cylinders, with no need for lifting devices and no effort for the operator. The new version of iFlex features further improvements in the converting section, such as the addition of the sheeting station and the evolution of the exclusive Rock’n’Roll matrix stripping unit, now with “Dual Function” capability to provide higher stripping performance with all kind of label shapes. It can work in two different ways according to the type of substrate and the die-cutting shape: either as contact-style or as tower-style system.

is the web magazine with all news about OMET Group

is the web magazine with all news about OMET Group