Dual-shape labels: external and internal die-cutting shape

OMET technology and innovation, in collaboration with the passion and enthusiasm of Grafiche Amadeo, managed to elevate the latest OMET installation on a higher performance level, with the production of special labels with double die-cutting shape, without backing removal. This specific configuration is applied on an 8-color XFlex X2 370.

Grafiche Amadeo entered the label business with the purchase of two OMET narrow-web flexo presses in 3 years. The second XFlex X2 was equipped with innovative technical solutions developed on the specific request of the customer. OMET designed a tailor-made solution for the production of dual-shape labels based on the addition of a die-cutting station in-between the flexo units and on an accurate use of the glues.

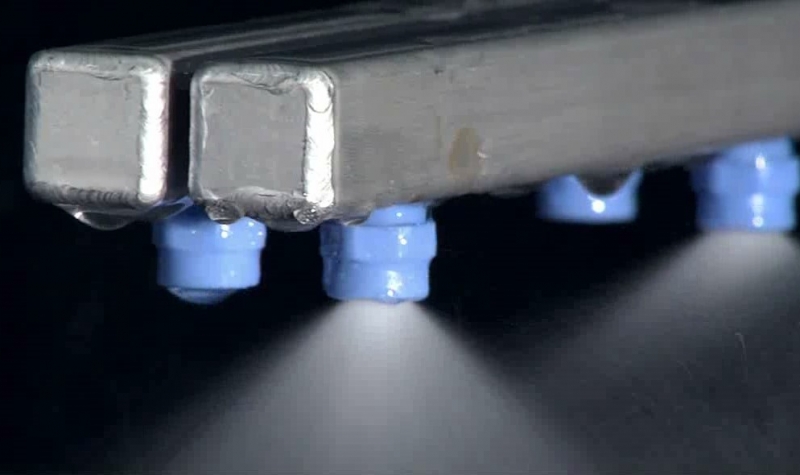

The machine was especially designed with a particular layout that enables the removal of the internal part of the label, by cutting and removing it before the stripping unit. The die-cutting unit installed in-between the last 2 printing groups cuts the shape meant to be removed, without touching the backing, thus preventing the support from being punched, as it usually happens.

Andrea Delfino, Responsible for label sector at Grafiche Amadeo, explains: “After the cutting process, we use a Cold Foil and a flexo unit to apply a layer of UV glue on the shape already die-cut, to facilitate its removal. The label and the filmic substrate are coupled by mean of a nip roll, the UV lamp activates the glue and the removable shape sticks to the plastic film that strips it away. The following steps consist in traditional die-cutting process and matrix rewinding to obtain a special label with both internal and external die-cutting shapes.

Mr. Delfino continues: “Thanks to OMET technology implemented on XFlex X2 and to a wise substrate handling, the working speed of this press can reach 130 m/min”. The application of a layer of glue killer under the shape to be removed is a crucial step for the success of the entire job. When the adhesive material is separated from the backing, this particular substance is spread onto the area corresponding to the removable shape, weakening the strength of the glue in order to facilitate the stripping process. Without this special glue killer, the maximum printing speed would be dramatically slower.

OMET had already integrated this special configuration with the die-cutting unit in-between two printing groups on an XFlex X6, fully automatic and high-performance machine. Yet, Grafiche Amadeo’s X2 is the first machine to implement this very application on a completely mechanical platform.

is the web magazine with all news about OMET Group

is the web magazine with all news about OMET Group